Warp Protector Motion

- textilecoach

- Sep 13, 2021

- 3 min read

Warp Protector Motion

Warp protector motions protect the warp in the event of shuttle trap which may be due to over picking. The mechanism will prevent mass breakages.

Following are types of warp protector motions.

Loose reed mechanism

Fast reed mechanism

Loose reed mechanism:

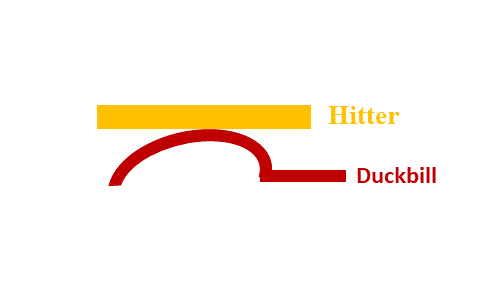

As the name indicates the reed is loose, when the shuttle traps in the shed. The reed is supported by its cam on top bottom by arm. The arm is connected to stop reed through duck bill assembly. The duckbills is made up of mild steel and is curved in shape and will pass below the hitter which is also curved. During the normal condition both will have the following type of arrangement. This gives maximum support to reed.

The hitter is made up of cast iron and fixed to front rest. The one end of stop rod carries a finger made up of cast iron and other end carries antifriction bowl riding on bow spring made up of mild steel. When crank is at back center, the bowl will be at the center of bow spring. So that maximum firmness is given to reed. Bow spring is connected to loom front. The stop rod finger made up of cast iron is fixed to stop reed which is also made up of cast iron. The finger will be facing the hitter.

Working:

In the normal condition bowl will be on bow spring and duckbill passes below the hitter and the reed is firm. If shuttle is trapped, reed opens and reed arm moves back and thus the duckbill will move above the hitter. This causes the stop rod finger to touch hitter. The loom is stopped when the starting handle is pushed back.

Setting:

Following are timings and settings for proper functioning.

Keep the crank at back center, so that the bowl is exactly at the center of the bow spring.

Keep the crank at front center and then set the distance between duckbill and heater by 1/8 inch if necessary.

Uses of loose reed motion:

Loose reed mechanism is used for normally shorter width fabrics and for light weight fabrics.

It is may be found on either over pick or under pick looms.

The loose reed loom run faster than fast reed loom.

Fast reed mechanism:

The arrangement consists of swell in the box connected directly to dagger which will be facing frog. The frog is fixed to loom frame(side rail). The frog is connected to starting handle. The dagger is connected to spring as it is negative in motion.

Working:

When shuttle is housed in the box, the swell moves back and thus the dagger will be above the frog and the loom does not stop.

If shuttle fails to reach the box, the swell will not move, and thus the dagger will be inclined with frog. When crank approaches front center, dagger pushes the frog and frog pushes the starting handle.

Loom banging:

When shuttle is not there in the box, if the loom is operated or working, the dagger will hit the frog resulting in a large sound known as banging. This causes high wear and tear.

To overcome this problem flat springs are connected to starting handle.

Following is material of construction:

Dagger: It is made up of cast iron as it should be sturdy.

Swell: It is made up of mild steel so that is will be sensitive to shuttle movement.

Frog: It is made up of cast iron so that it will be sturdy for banging's.

Flat springs: It is made up of cast iron if the spring is in the form of a slab

It is made up of mild steel if it is in the form of bow spring.

Setting and Timing:

Keep the crank at front center so that the dagger should be touching frog when box is empty.

Crank at front center, lift the dagger above the frog and set with a distance of ¼ inch to ½ inch.

Uses of fast reed motion:

Fast reed mechanism is used for normally heavy weight and wider width fabrics.

Can you help us improve this page?

Send us your contribution on info@textilecoach.net, we will update this page and give you proper attribution!

Comments